Transform mining with immersive virtual reality

Visualize and manage your mine from anywhere in the world with Dataverso

Optimize Geological Management with

Immersive Virtual Reality Solutions

Dataverso has been designed by a team of technology and mining experts, driven by a passion for innovation and sustainability

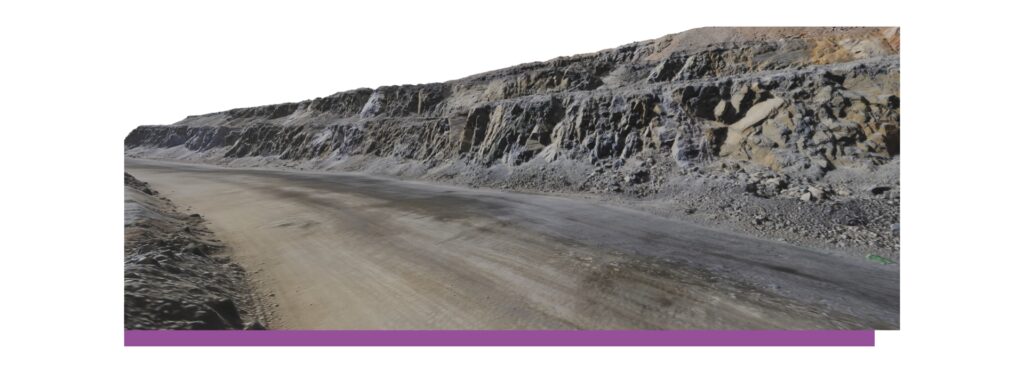

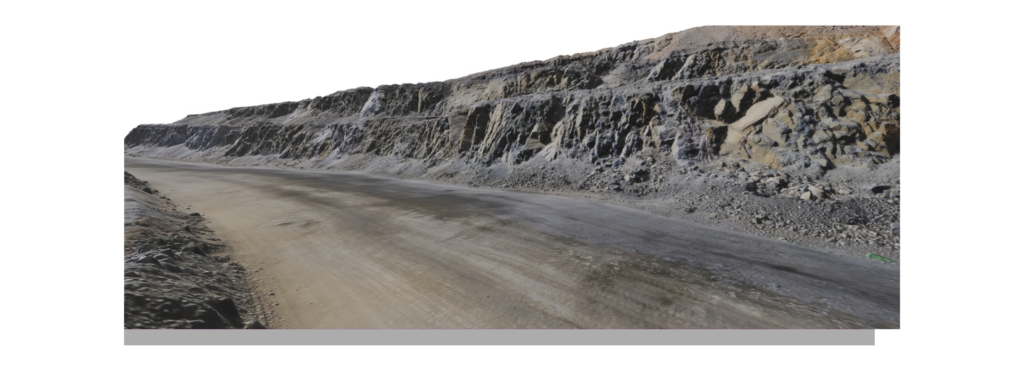

We have developed a tool that combines photogrammetric processing with immersive virtual reality, allowing you to visualize and explore the mine from anywhere in the world.

Geotechnical Operations

Safety

Enhance the safety of your workforce by reducing professionals’ exposure to high-risk zones in productive areas of the mine. At the same time, it enables geological and geotechnical teams to work securely from anywhere in the world.

Cost Reduction

With advanced features that streamline processes and provide more accurate data, Dataverso lowers operational costs, speeding up geological and geotechnical reconciliation.

Technological Innovation

Through virtual reality, Dataverso provides a comprehensive view of the mine to geological and geotechnical teams, as well as decision-makers, accelerating reconciliation processes and data-driven decision-making.

Time Saving

Dataverso accelerates geological measurement and analysis times, enabling efficient process reconciliation and effective real-time decision-making.

Reliability of Information

By integrating the freedom of movement and perspective in Dataverso, along with the availability of extensive slope surfaces, it is possible to correlate structural information across multiple benches, allowing the recording of the actual persistence of structures, a limitation that geologists currently face in bench mapping. This strengthens the structural model, a fundamental variable in geotechnical modeling and stability analysis.

Higher Efficiency

Fast and easy access to results through virtual reality speeds up collaboration between teams and enhances decision-making efficiency.

Reduction of the Carbon Footprint

We contribute to the reduction of the carbon footprint by allowing a reduction in travel to the mine, in turn contributing to the circular economy.

Revolutionize Geological and

Geotechnical Operations

Safety

Enhance the safety of your workforce by reducing professionals’ exposure to high-risk zones in productive areas of the mine. At the same time, it enables geological and geotechnical teams to work securely from anywhere in the world.

Cost Reduction

With advanced features that streamline processes and provide more accurate data, Dataverso lowers operational costs, speeding up geological and geotechnical reconciliation.

Technological Innovation

Through virtual reality, Dataverso provides a comprehensive view of the mine to geological and geotechnical teams, as well as decision-makers, accelerating reconciliation processes and data-driven decision-making.

Time Saving

Dataverso accelerates geological measurement and analysis times, enabling efficient process reconciliation and effective real-time decision-making.

Reliability of Information

By integrating the freedom of movement and perspective in Dataverso, along with the availability of extensive slope surfaces, it is possible to correlate structural information across multiple benches, allowing the recording of the actual persistence of structures, a limitation that geologists currently face in bench mapping. This strengthens the structural model, a fundamental variable in geotechnical modeling and stability analysis.

Higher Efficiency

Fast and easy access to results through virtual reality speeds up collaboration between teams and enhances decision-making efficiency.

Reduction of the Carbon Footprint

We contribute to the reduction of the carbon footprint by allowing a reduction in travel to the mine, in turn contributing to the circular economy.

Key Benefits

Significant reduction in physical exposure during work on slopes, increasing operational safety.

Elimination of the risk associated with physical presence on site since the analysis is carried out remotely and safely using immersive technology.

Significant reduction in the carbon footprint by minimizing the need for travel and physical operations.

Functionalities

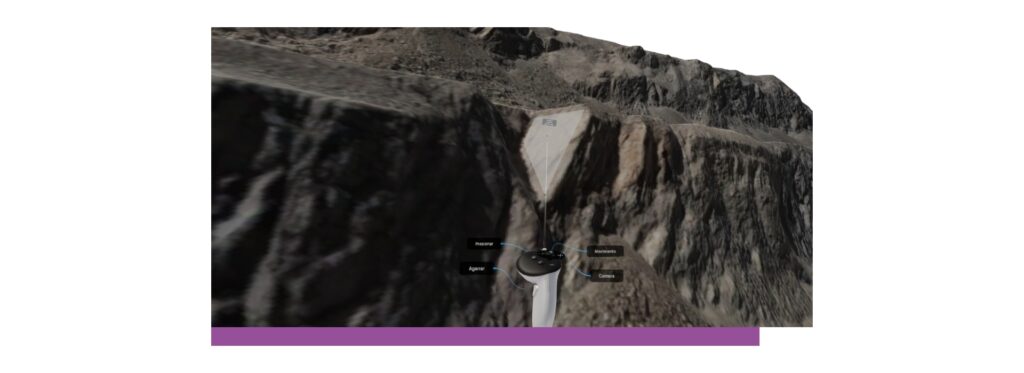

Conduct detailed and collaborative inspections of geotechnical conditions. Review mine benches individually or as a team, assess berm widths, identify over-excavations, and detect potential wedges or planar failures. You can also examine special geological and structural elements and calculate the condition factor.

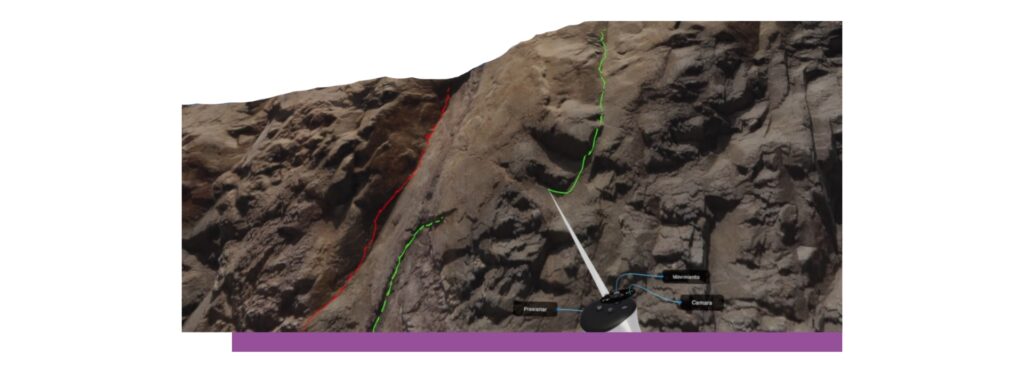

Identify and accurately characterize structural discontinuities. Obtain key descriptive parameters, such as dip angle, dip direction, persistence, spacing, sinuosity, and the thickness of the fault damage zone. This allows you to capture structural information efficiently and accurately.

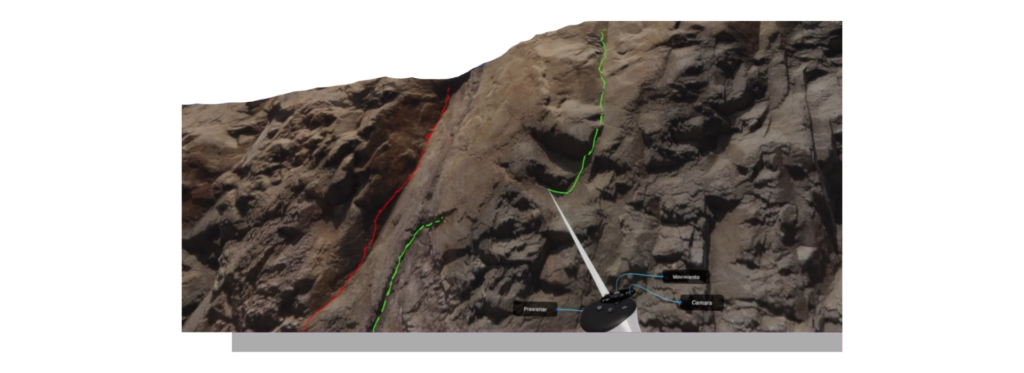

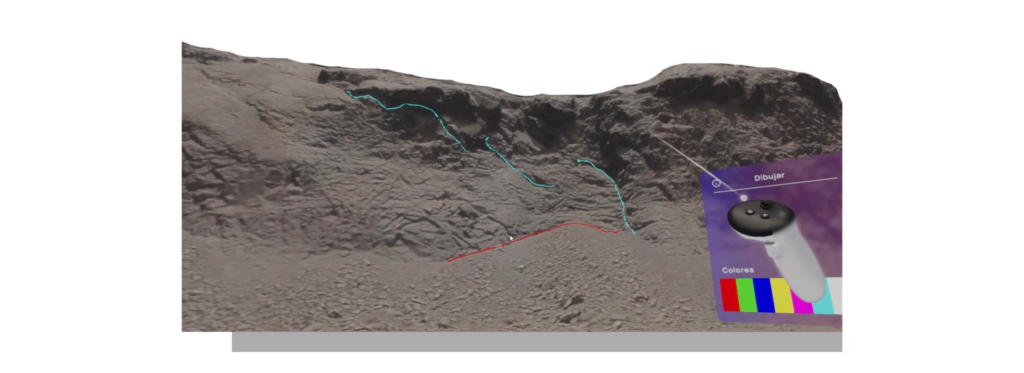

Compare models with immersive surveys and track the evolution of structures. Identify new structures, verify the continuity of existing ones, detect shear relationships, and adjust fault traces to maintain full control over the structural stability of your operation.

Precisely estimate the condition factor of slopes. Based on the recording of geometric and geotechnical parameters, evaluate the safety and stability of slopes, ensuring that all structures meet the required standards for safe operations.

Tools

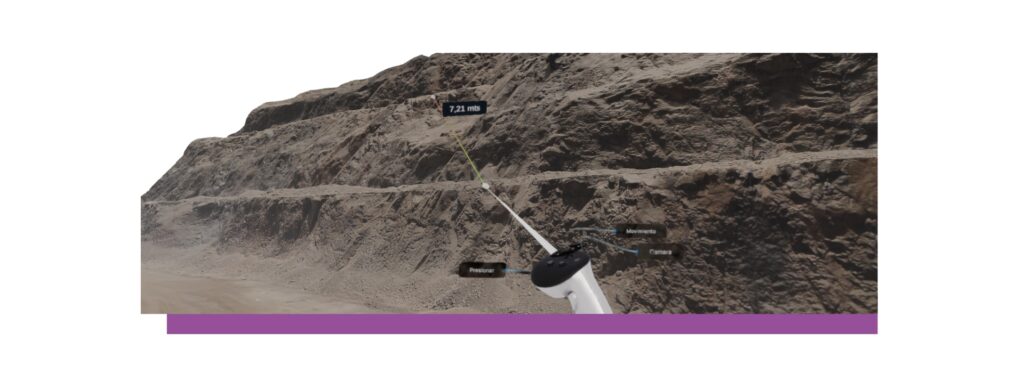

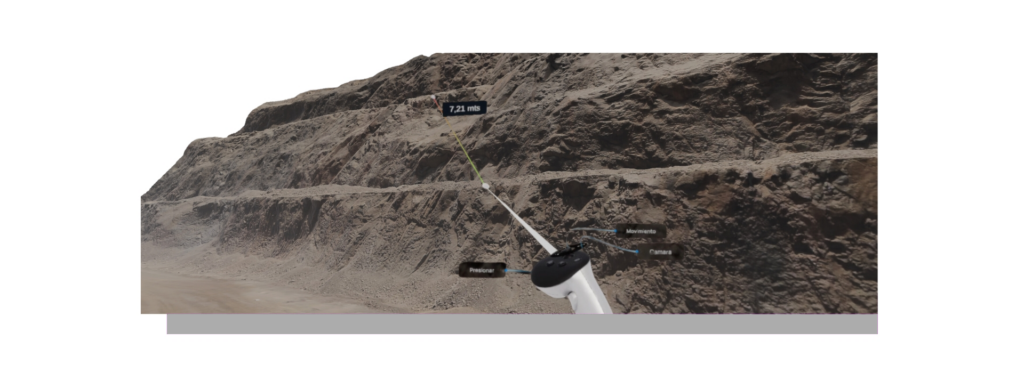

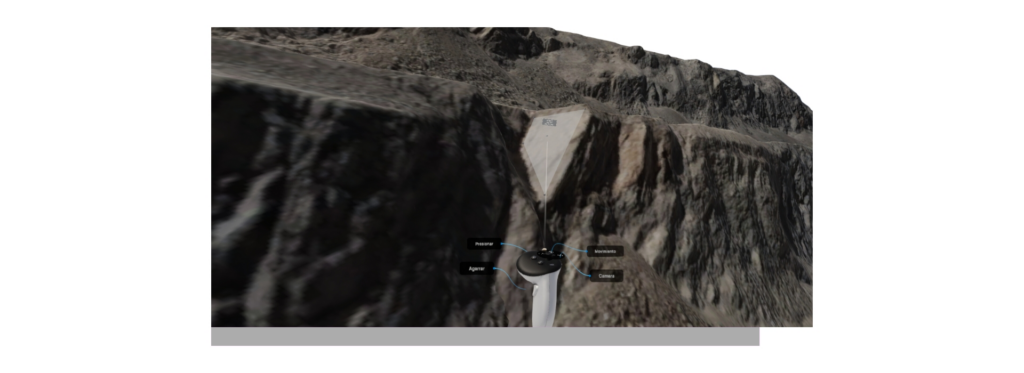

The Ruler tool empowers users to precisely measure distances between a variety of geotechnical and structural elements. It facilitates the measurement of berm and ramp widths, structural spacing, cracks, structural displacements, and other critical components essential for comprehensive geotechnical assessments.

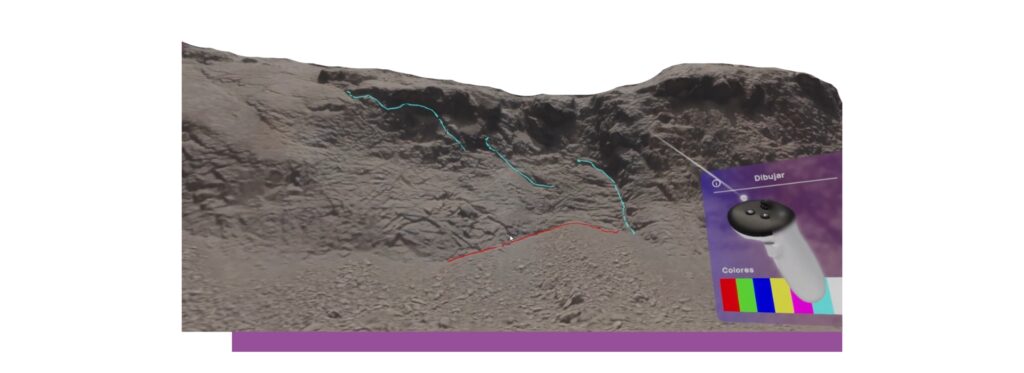

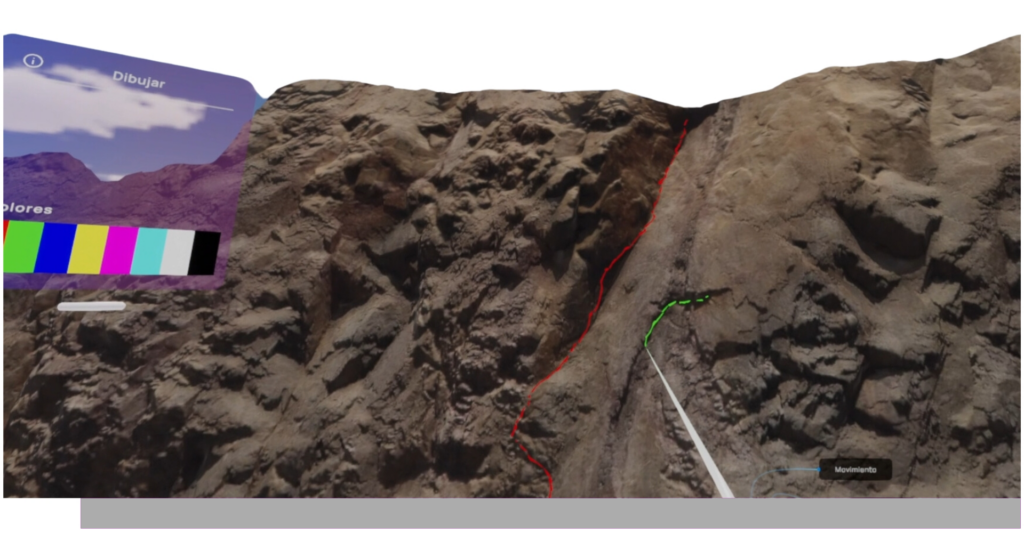

Draw lines in up to eight distinct colors, create polygons, project structures, and track significant faults. This versatile functionality enhances the correlation of structural information, offering a clear and precise visual representation of geotechnical and geological data, facilitating comprehensive analysis and informed decision-making.

Provides users with the precise capability to effortlessly remove any drawing or measurement elements that are outdated or require modification. This functionality ensures total control over the displayed content, empowering teams to maintain data that is consistently current and accurate.

Uploading and downloading of lines, profiles, and surfaces, along with the capability to export information in PNG and various other compatible formats. This functionality significantly enhances the integration of data collected and analyzed with other systems and software platforms, improving efficiency and interoperability throughout the mining operational workflow.

Enables the mapping of the condition factor by considering variables such as visible gutters, induced cracks, minor discontinuity conditions, presence of unstable blocks, slope profile geometry, and the condition of the slope crest.

Testimonials

The Dataverso class session was an incredibly impactful experience. The integration of theory and practical application in a virtual environment left a lasting impression on both students and instructors. The opportunity for real-time collaboration within the software greatly enhanced the learning experience, garnering outstanding feedback for its immersive and realistic virtual spaces.

I have had the privilege of witnessing two versions of Dataverso, and the evolution has been nothing short of remarkable. The latest version introduces the capability to capture and store data specifically for engineering analysis, significantly enhancing the value it brings to our operations. Moreover, the ability to conduct collaborative work sessions in a risk-free environment has truly transformed our approach to tackling geotechnical challenges.

The collaboration between Dataverso and Minverso has ushered in a new era of innovative technologies that were once considered unattainable in the mining industry. The capability to access the deepest sections of the mine from virtually anywhere, all while maintaining the highest standards of safety and work quality, signifies a profound paradigm shift in the operational dynamics of the mining sector.